Northern Plains Drainage Systems

Tile Drainage Equipment, Emlid GNSS, Municipal Drainage

Call Us at

1-877-354-2899

Ext. 1 for Emlid Products

Ext. 5 for Tile Drainage Equipment, Pipe, and all other enquiries

What We Do

Tile Drainage Equipment

Your trusted source for tile drainage equipment in western Canada. Our expertise and experience sets us apart as the leading supplier for farmer self installers.

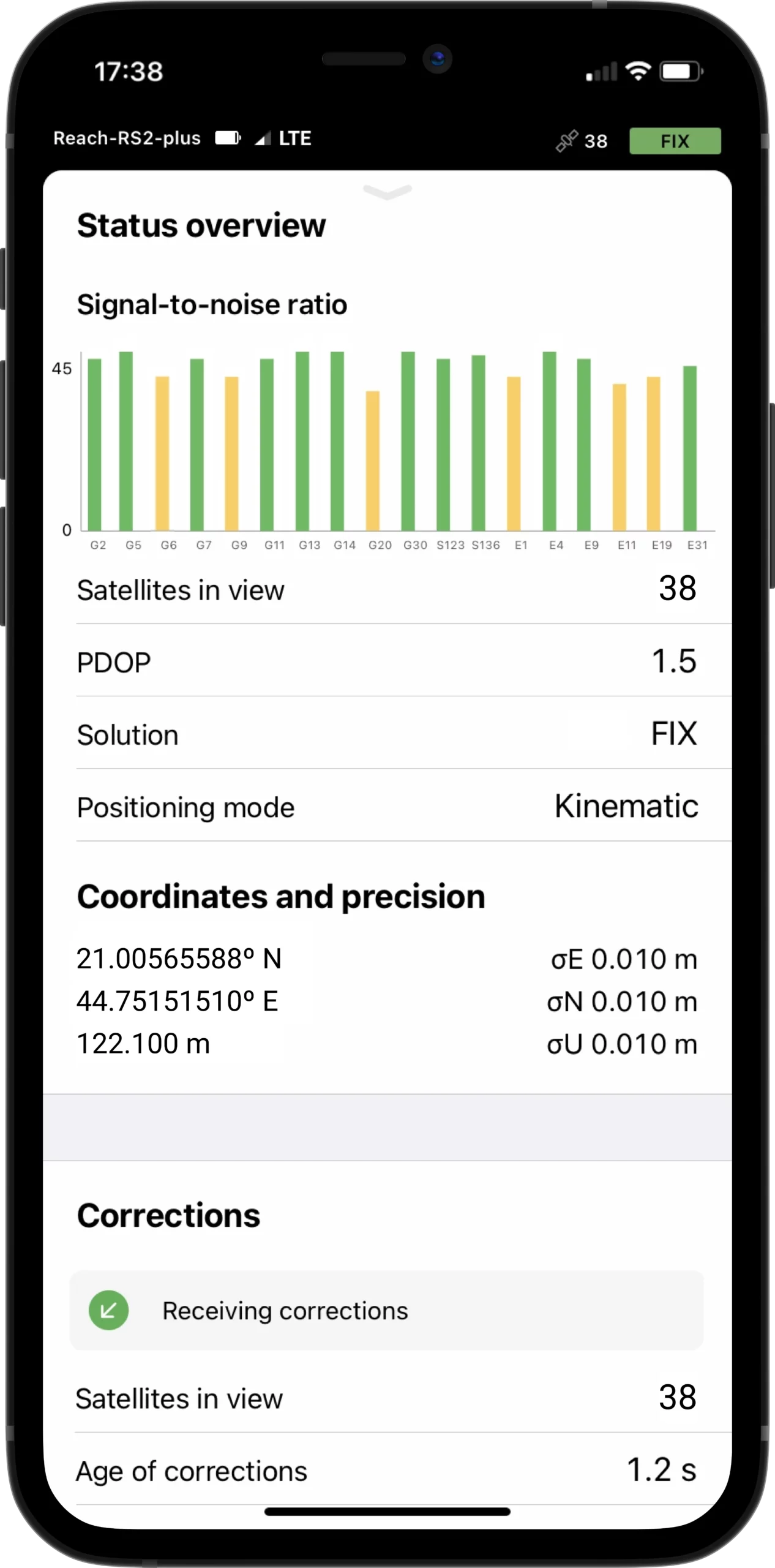

Emlid Reach RS3 RTK

RTK GPS/GNSS receiver with tilt compensation. Affordable survey grade precision for precision agriculture, municipal, and construction applications.

Municipal Drainage

Manitoba’s most trusted supplier of municipal ditch and culvert drainage surveying and plotting. Our work is highly respected and meets al standards specified by Manitoba Water Stewardship.

Ditch Assist by Northern Plains Drainage Systems

Ditch Assist™ and Ditch Assist X™

We’re also the creators of Ditch Assist™ and Ditch Assist X™

Ditch Assist is the complete solution for automated machine control for ditching, land leveling, 3D land forming, and simple tiling.

Ditch Assist X keeps you on grade when digging with a backhoe or excavator.

Tile Drainage Equipment

Because they aren’t making any more land

If maximizing yields and reducing in-field variability caused by excess moisture makes sense to you, then you should consider tile drainage.

Imagine not having to farm around waterlogged areas or lose crops to flooding. That’s what tile drainage can do for you. It’s not just about higher yields – it’s about reclaiming those problem areas and getting consistent results year after year. Many farmers see their investment in tiling equipment pay off in just one wet season!

Why Tile Yourself?

Forget the frustration of finding contractors for smaller tile jobs. What if you only want to target your problem areas? Own your tiling equipment and choose where and when to improve your land – it’s a great investment in your farm’s future. Owning your equipment puts you in control – tile when and where you need it, without relying on contractors.

Soil-Max Tile Plows. ADS Pipe. Training & Support.

Emlid Reach RS3 RTK GNSS

RTK GNSS receiver with tilt compensation

Survey grade precision for precision agriculture and beyond

Our goal is to make precision farming affordable. Get the survey-grade accuracy you need for machine control and field work with the Emlid Reach RS3 – a powerful RTK solution that’s easy on your budget. Stop overpaying for accuracy – this versatile system tackles everything from machine control to precise field layout.

Municipal Ditch & Culvert Surveys and Plotting for Drainage Licensing

We have been providing these survey and plotting services to Manitoba municipalities since 2011, and have surveyed more than a thousand miles of ditches. Our data collection and data processing workflows are streamlined, a result of what we’ve learned through experience. The products we deliver to our clients are highly valued by those using them to implement the drainage works.