Request a No Obligation Quote Today

Some of the Benefits of Tile Drainage

- Improved soil structure: By removing excess water, tile drainage helps to maintain optimal soil moisture levels and improve soil structure, which can result in better root growth and increased crop yields.

- Increased production: By reducing waterlogging, tile drainage can increase the amount of land that can be used for agriculture, leading to increased crop production and profitability.

- Enhanced soil aeration: By removing excess water, tile drainage helps to maintain a better balance of oxygen and water in the soil, which can enhance soil aeration and root respiration, leading to healthier crops.

- Reduced soil erosion: By controlling water flow and reducing erosion, tile drainage can help to maintain the integrity of fields and protect against soil degradation.

- Improved water management: Tile drainage can also be used to manage irrigation water more effectively, reducing the amount of water required to irrigate crops and improving water use efficiency.

Soil-Max Tile Plow Sales in Western Canada

TRAIL-BLAZERS WANTED! You can tile your land yourself, and achieve professional results. We have helped many farms throughout western Canada do just that. The Soil-Max Stealth ZD tile plow is the best-selling plow in North America because it really does make tiling your own land achievable and affordable. The sooner you start the sooner you see the benefits.

Soil-Max Gold Digger Stealth ZD Tile Drainage Plow

Wherever you are in western Canada, we will come and setup your plow and train you in plow operation and best practices…plus provide all the support you need going forward. We’ve been tiling with and selling these plows for over 10 years. If you run into an issue we’ve probably come across it already!

Introducing the Soil-Max Stealth ZD Tile Plow Range

- Manufactured from T1 Steel, allowing twice the tensile strength with half the weight.

- 2 ¼” of t1 is = to 6” of mild steel in strength.

- Thinner profile shank = easier pulling through the soil.

- Lifting action lifting soil through the entire soil profile to make less drag on the plow.

- Installation of 3” to 10” tile by changing quick change poly sided boots and shear.

- Trapezoidal shaped shear and contoured boots to match tile size and maintain tile trench from beginning to end for accurate pipe placement.

- Zero deflection produces better grade control with the tile exit point directly below the hinge point of the pitch plow.

- Proprietary proportional valve to make crucial incremental adjustments to keep your plow on grade.

- Available options: PWM controlled tile feeder, walking tandems.

Request a No Obligation Quote Today

STEALTH ZD TILE PLOW

FEATURES

All of the above as well as…

– 6.5’ working depth.

– Easy single pin connection to hitch.

– Single point hydraulic hook-up to tractor.

– Proprietary down pressure manifold puts only necessary pressure on the wing wheels, ensuring that pipe being installed in the soil profile is being done correctly and is unaffected by surface conditions.

STEALTH ZD TILE PLOW

FEATURES

– 5.5’ working depth.

– Easy connecting 3pt in Cat III or Cat IV.

– Can be used on tractors as small as 20,000 lbs.

STEALTH ZD TILE PLOW

FEATURES

Mini Plow Ideal for Small Projects

– Needs a minimum of a 8,000 lb tractor.

– 4′ maximum working depth.

– Installation of 2” to 4” tile by changing quick change poly sided boots and shear.

– Poly sides that shed dirt and makes for an easier pull.

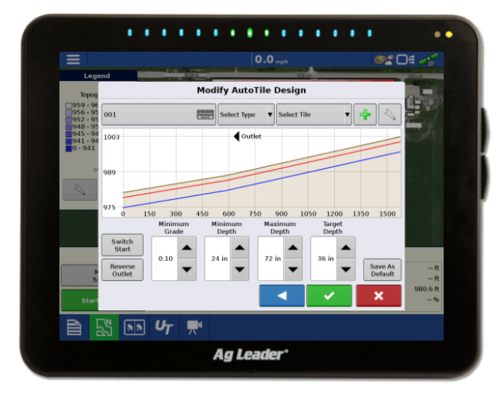

Ag Leader InCommand® with Intellislope® Plow Control

InCommand displays with Intellislope® technology assist you in controlling the plow to install drainage tile on grade throughout the entire run. Perfectly drained fields are easily attainable with the right technology – at a fraction of the cost of hiring it done.

Automated grade calculations with AutoTile

AutoTile mode makes grade calculations based on the survey and target elevation and automatically adjust depth of the plow.

Flexibility to adjust as you go

If you want more control, grade control mode uses GPS instead of complicated lasers to install at desired grade. Grade settings can easily be manually adjusted as you go from the cab instead of a laser tripod. If needed, you can also use grade breaks to shallow up but keep the same grade.

Automated pitch control if signal is lost

If your RTK GPS signal is lost, use Pitch Control mode (with a pitch plow) to finish the run. Intended to keep you at your desired pitch in case of a lost signal but is not meant for large-scale installs.

3 Easy Steps to Tile Installation

1. SURVEY

Can be done ahead of time with an ATV, or at the time of installation with the tile plow utilizing RTK GPS. Collect surveys by driving over the path where tile needs to be placed to collect the surface elevation.

2. PLAN

Enter the desired minimum/maximum and target depths, as well as the minimum grade to drain excess water from the field. This can be done in the field or with the SMS™ Advanced Water Management Module.

3. INSTALL

Let InCommand with Intellislope do the work of precise control of the tile plow. The AutoTile mode will automatically adjust depth of the plow automatically or use manual grade or pitch control modes.

TILE DRAINAGE FAQ

What is tile drainage?

Tile drainage is a system of underground pipes that are installed to remove excess water from agricultural land, making it possible to cultivate crops in areas with high water tables or poorly drained soils.

What are the benefits of tile drainage?

Tile drainage can increase crop yields, improve soil structure, and reduce soil erosion. It can also reduce the risk of waterlogged soils and help to prevent disease and pest problems.

How does tile drainage work?

Tile drainage works by collecting excess water from the soil and directing it to an outlet, such as a ditch, stream, or other watercourse. The water is then carried away from the field, reducing the risk of waterlogging and improving soil structure.

What types of soils are suitable for tile drainage?

How is tile drainage installed?

Tile drainage is typically installed using a machine called a tile plow. The plow creates a trench in the soil and the drainage tile is then placed in the trench. The trench is then filled with soil and compacted to ensure a tight seal.

How much does tile drainage cost?

The cost of tile drainage will depend on several factors, including the size of the field, the type of soil, and the type of drainage system used. It can be a significant investment, but the benefits of improved crop yields and reduced disease and pest problems can often offset the costs.

What are the maintenance requirements for tile drainage systems?

Tile drainage systems require relatively little maintenance. The primary concern is to keep the drainage tiles free of debris, which can clog the system and reduce its effectiveness.

Can tile drainage systems be retrofitted to existing fields?

Yes, tile drainage systems can be retrofitted to existing fields. The installation process involves digging a trench and installing the drainage tile. The trench is then filled with soil and compacted to ensure a tight seal.

Introducing the Soil-Max Gold Digger Stealth ZD Tile Drainage Plow

Wherever you are in western Canada, we will come and setup your plow and train you in plow operation and best practices…plus provide all the support you need going forward. We’ve been tiling with and selling these plows for over 10 years. If you run into an issue we’ve probably come across it already!

Request a No Obligation Quote Today